Kiln Dried Wood – Why Moisture Readings are Important

When first harvested, lumber is “green” – meaning it’s not been dried. Since green lumber is very moist, it can warp and always will shrink for every percent of moisture content (MC) below the fiber saturation point. This can occur regardless of the drying method.

- Kiln Drying Is Not Permanent

- Kiln Drying Your Own Wood

- Moisture Readings are Important

- Two Types of Moisture Meters

- How to Kiln Dry Wood

When lumber companies kiln dry their wood, they do so in a controlled environment using carefully monitored temperature and humidity levels in order to avoid over-drying or under-drying. This is critical because it allows the wood to dry to the correct MC for its ultimate intended use, thereby enabling the wood to maintain stability and dimension.

Wood that is over dried or under dried will warp or shrink and will not have the correct MC for its intended use.

Depending on its final use, kiln-dried woods are dried to a specific MC range. For example, wood that is intended for musical instruments or indoor furniture is dried to a range of 6-8% MC. Wood that is intended for outdoors, such as lumber used for framing a house, may be dried to a range of 17-19% MC.

Kiln Drying Is Not Permanent

Some people mistakenly believe that kiln drying is permanent and that a pile of lumber stamped “certified kiln-dried” will always be good to use as is.

Wood is hygroscopic, which means it can absorb or release moisture. The moisture might be a direct water source such as rain, moisture in an adjacent material, or even humidity in the air.

This nature of wood to absorb or release moisture applies to any wood – even kiln-dried wood.

Therefore, when a woodworker buys kiln-dried wood, all he can be assured of is that the lumber went through a kiln-drying process. He has no assurance the lumber has been dried properly (to avoid shrinkage stresses that occur), that it has been dried to the desired MC, or that the wood hasn’t regained moisture after being kiln dried.

This last point is very important to understand. Once the kiln-dried wood leaves the lumber company, its MC can change at any time – during transportation, manufacturing, or even when stored in a woodworker’s garage or shed.

Kiln Drying Your Own Wood

Kiln-dried lumber can be expensive. Therefore, woodworkers may want to dry their own wood to help assure they are getting the MC they want.

One option is for woodworkers to air dry green wood. Air drying, however, can take several months and will generally not achieve a low enough MC without the additional step of kiln drying.

A simpler, cheaper, and safer way for woodworkers to dry green wood quickly is with their own solar kilns. Building a backyard solar kiln is relatively inexpensive and they are easy to operate.

In the words of Dr. Gene Wengert, President of The Wood Doctor’s RX, LLC and a former extension forest products specialist at the University of Wisconsin-Madison, who developed a highly popular and simple solar kiln design in 1978, “Solar kilns won’t dry wood too fast. It’s pretty much a ‘set it and forget it’ system.”

In other words, woodworkers can just put the wood in there and almost forget it.

“It’s only near the end of the drying when you need to measure MC to determine if it’s time to stop the process and pull the wood out,” Dr. Wengert adds.

Moisture Readings are Important

When first learning to dry lumber, especially lumber thicker than one inch, woodworkers should monitor MC daily to avoid drying too rapidly. The best way to do this is with a moisture meter.

Using a moisture meter, woodworkers can monitor the drying rate by measuring the MC of the sample boards and comparing the daily rate of moisture loss with the “safe rate” for that species. The safe rate refers to the loss of moisture in one day.

Safe rates for drying 1- or 2-inch thick lumber from different species are available in safe rate tables. These safe rates must be followed until lumber MC drops to 20%. Exceeding the safe drying rate for a given species can cause defects in the lumber.

Dr. Wengert recommends identifying sample boards at the start to determine MC loss rate. These are boards that may have started out with a higher MC than the rest of the load, were cut more recently than the others, or are a little thicker.

“If you check the sample pieces and they’re too wet, you’re going to continue drying,” says Dr. Wengert. “You want to make sure your sample pieces are dry enough before you stop drying. It doesn’t really matter if half the load is ready to be pulled out.

“So don’t pull the load based on the average. We usually pull the load based on the wettest pieces. The wettest has to be dry enough,” he says.

Two Types of Moisture Meters

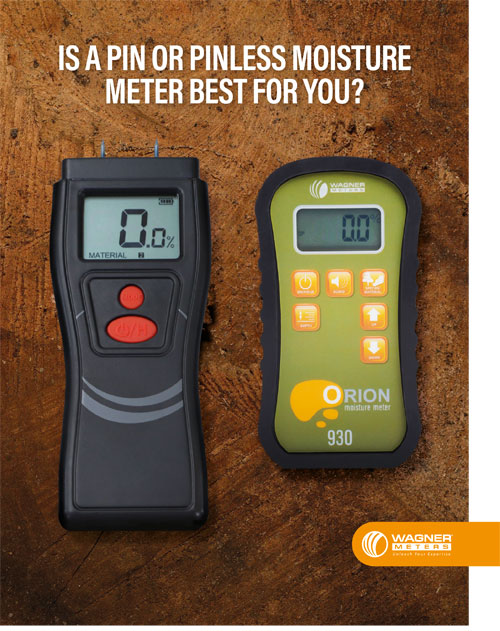

Woodworkers have a choice when it comes to selecting a moisture meter. They can either go with a pin meter or a pinless meter. Each has its advantages and disadvantages.

One advantage of pin meters (only those that use longer pins with insulated shafts) is that wood can be tested for moisture at different depths. The major disadvantages are the relatively small area tested with each insertion, their sensitivity to wood temperature, and the damage the pins do to the wood surface. The pins can also break or give inaccurate readings when improperly inserted.

Pinless meters, on the other hand, don’t penetrate the wood’s surface, so they won’t damage the wood. Another advantage is that a woodworker can “scan” many board feet of wood simply and quickly.

Pinless meters take a composite average of the MC from the surface to about 1 inch deep in most cases, and the readings are obtained from a greater surface area than pin meters. They do, however, require sufficient pressure to give a correct reading and may also be susceptible to damage on the sensing pad.

Wagner Meters, one of the leading American manufacturers of American pinless moisture meters, provides moisture meters equipped with IntelliSense™ technology. This allows accurate readings deep in the wood, virtually unaffected by surface moisture.

Wagner meters with dual depth measurement modes – a deep mode and a shallow mode – are also available (see the Orion 930, 940, and 950).

Wagner has models for woodworkers who need to measure wood moisture in all wood species – from the more common softwoods and hardwoods to rare tropical species.

How to Kiln Dry Wood

There are several resources available that not only provide plans for building a home-based kiln, but which also go into greater detail about kiln-dried wood and kiln operation. Here are some to consider:

There’s the plan mentioned above, developed by Dr. Wengert. It is popularly referred to as the “Virginia Tech Solar Kiln” because Dr. Wengert developed it while working at Virginia Tech. It’s considered the standard by which other kilns are built.

More recently, Dr. Brian Bond, Assistant Professor and Extension Specialist, Department of Wood Science and Forest Products, Virginia Tech, added color photos and re-formatted Dr. Wengert’s original plans. It’s called “Design and Operation of a Solar-Heated Dry Kiln.” You can download it for free here.

Dr. Bond also offers a two-day workshop on drying lumber with a solar dry kiln. It’s held around the last week of every May in Blacksburg, Va., and introduces all the principles of drying hardwood and softwood lumber in a solar kiln. The workshop also includes information on the design and operation of solar kilns and features a tour of the solar kiln at Virginia Tech.

Free Download – Is a Pin or Pinless Moisture Meter Best For You?

WOOD magazine has an excellent article on building a solar kiln called “WOOD Magazine Builds a Solar Kiln…with a Little Help from Our Friends.” To access it, click here.

The article contains an offer for the complete plans and a materials list for building a 1,000-board-foot capacity solar kiln. Incidentally, it’s based on Dr. Wengert’s original design. The cost for the plans and materials list is $9.95 plus $4.95 S&H. To order, call toll-free 1-888-636-4478.

Although woodworkers have several different types of kilns to choose from for drying lumber, the kiln-drying resources offered above are for kilns that are inexpensive to construct and simple to operate.

Summary

For the hobbyist or professional woodworker who wants to save money and avoid the high cost of commercially kiln-dried lumber, a homemade solar kiln may be the best option.

They’re relatively inexpensive to build and easy to operate. In addition, other than the small cost of electricity needed to run the fans, they cost only pennies a day to operate.

To ensure a solar kiln doesn’t dry wood too fast, which can lead to costly defects, later on, woodworkers should use a moisture meter to frequently monitor the MC level. This will help prevent the finished wood product from cracking, warping, or splitting.

Read what happens when kiln drying doesn’t work.

Tony Morgan is a senior technician for Wagner Meters, where he serves on a team for product testing, development, and also customer service and training for moisture measurement products. Along with 19 years field experience for a number of electronics companies, Tony holds a B.A. in Management and his AAS in Electronics Technology.

Last updated on December 5th, 2025

I would like to build a small kiln for drying firewood. Approx 2 cords at a time. Have natural gas and electric available on site.

I own and operate a composite molding company and we have large Despatch Gas Curing oven that we would like to utilize for drying hardwoods. Are you familiar with using this type of oven for drying wood?

It is a gas-fired, closed air circulated system that can run multiple cure cycles up to 550 deg F.

Thank you,

Greg Brookes

Sherwood RTM Corp

Louisville, Ohio

Greg,

I am unfamiliar with that technology being used for drying of hardwoods. Certainly, the temperatures for drying hardwoods need to be much lower than that. 180°F is usually the maximum, and temperatures and general conditions need to be adjusted as the lumber is going through a typical hardwood drying schedule, such schedules generally being different depending on the species and thickness.

If you are going to attempt to Kiln Dry any Wood. You might be better off using a Vacuum Pump like those that are sold to repair Refrigeration Units on vehicles. If your Wood is placed within a Chamber that has been evacuated of the air surrounding us and heated. The Temperature required depending upon your Elevation might only be 90 Degrees. Where I live, I only have to Heat the Wood to 98 Degrees Fahrenheit for a period of 3 Days to achieve a 10% Relative Moisture Content.

Thank you for your input, Ronald.

I’m preparing my own business with a mobil sawmill and kiln. Do I need to get an “approval stamp” for my lumber or does it just matter where the lumber is being used? For example on framing for a house or framing for a shed. Or shelves or other furniture pieces or moldings in a house?

Josh:

You should contact your county inspector to determine that information, especially regarding structural framing members.

Regarding the interior wood pieces such as moulding or furniture, there should never be any necessary approvals. People make furniture all the time for their own use.

Before I buy the plans I am wondering what’s the ballpark number to build a dryer like the one above?

I live in florida and have some Pecan wood I want to dry out. I have a storage shed no electricity, no a/c, gets real warm. The pieces are 6.5 long15 inches wide, Three are6 quarter and two are 8. Currently at 35% according to surface MG. Will this type of setup work?

Richard, Our Wagner WoodH2O app will help you determine what the wood will equalize to given certain temperature and humidity values. This app is free and is available for iPhone and Android. Also, a good moisture meter will help you monitor the moisture content. I recommend our MMC205 or MMC210 found here: https://www.wagnermeters.com/moisture-meters/